× close

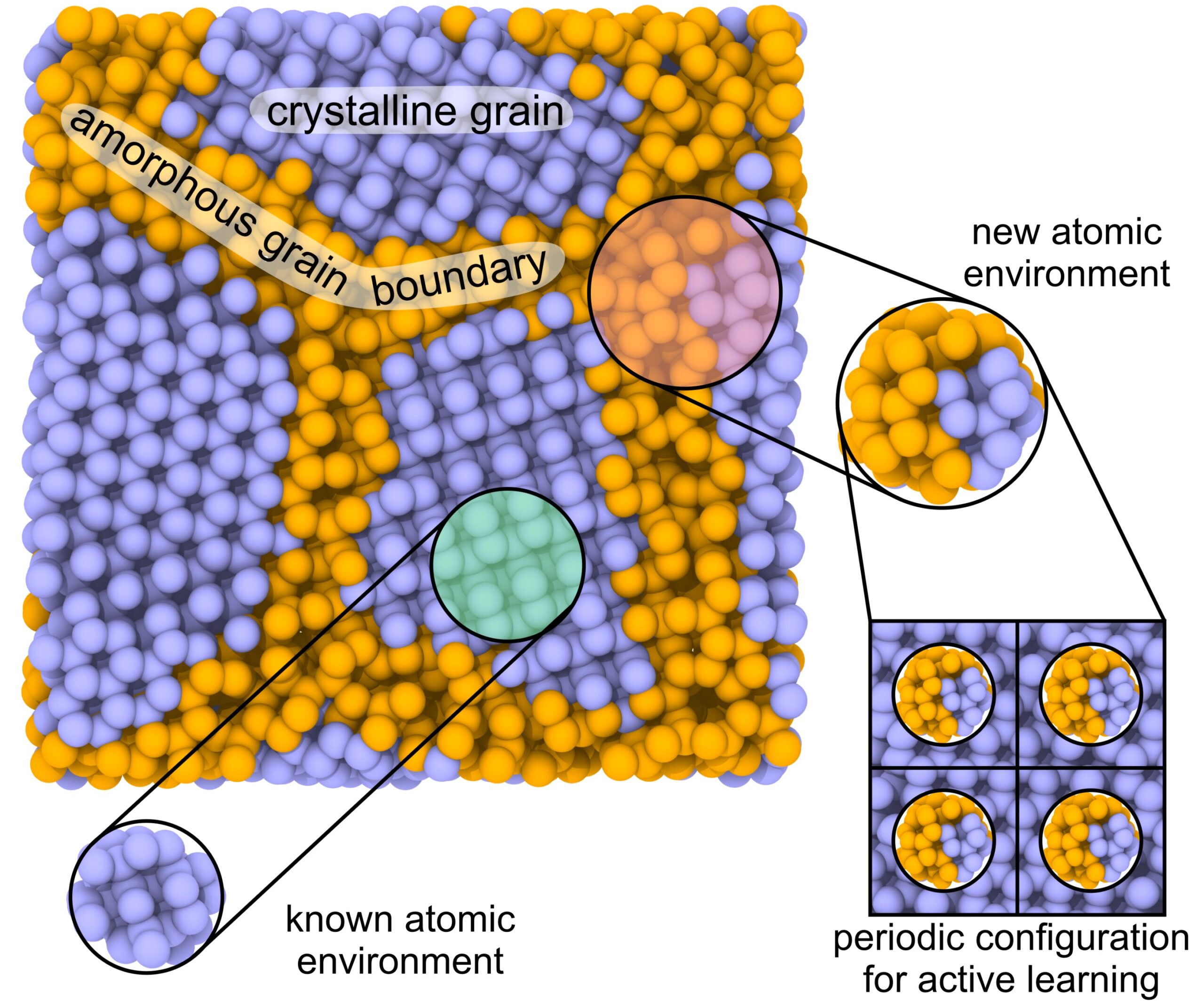

Schematic diagram of learning about the local atomic environment. The region highlighted by the red circle contains atoms with the highest extrapolated grade. These atoms are cut out of the structure and used to construct periodic configurations for further density functional theory calculations of energy, force, and stress. credit: Advanced theory and simulation (2024). DOI: 10.1002/adts.202301171

Skoltech’s research team has introduced a new method that uses machine learning to study the properties of polycrystalline, composite, and multiphase systems. This achieved a high degree of accuracy that is almost on par with quantum mechanical methods, which can only be applied to materials with fewer than a few hundred atoms.

The new method also benefits from active learning in the local atomic environment.The paper is published inside Advanced theory and simulation journal.

“Many industrial materials are synthesized as polycrystalline or multiphase systems. These materials contain both single crystals and amorphous components between single crystal grains. It is difficult to calculate the properties of these systems using modern quantum mechanical methods because of the density functional.This theory is only applicable to materials containing a few hundred atoms.

“To address this problem, we are using a machine learning approach based on moment tensor potentials (MTPs). These potentials were also developed at Skoltech under the guidance of Professor Alexander Shapeev.” , commented Faridun Jarolov, lead author of the study. student in the Skoltech PhD Materials Science and Engineering program.

Compared to other solutions, the authors recognize the potential of new methods in active learning in local atomic environments. When calculating large structures containing hundreds of thousands of atoms, MTP identifies which atoms are being calculated incorrectly or incorrectly. This may be because the training dataset is limited and cannot account for all possible system configurations.

This atom’s local environment is then “cut out” and its energy calculated using quantum mechanics. The data is then added back to the training set for further learning. As on-the-fly learning progresses, calculations continue until another configuration is found that should be included in the training process. Other known machine learning possibilities cannot learn on small local parts of large structures, which limits their applicability and accuracy.

“As an example, we studied the mechanical properties of polycrystalline diamond. Polycrystalline diamond is the hardest naturally occurring material and is often used in industry, such as in the manufacture of drilling rigs for oil wells. The results show that the mechanical properties of these polycrystalline diamonds depend on the particle size.The larger the particles, the more similar their properties are to those of single-crystalline diamonds. ” continued Jaroloff.

The authors believe that this approach not only allows the study of the mechanical properties of non-monocrystalline materials that are commonly synthesized and used in experiments, but also conducts comprehensive studies of polycrystalline and composite materials. It was pointed out that the data can be obtained as close as possible to the experimental results.

“In practical use, materials that are not perfectly crystalline are often used because perfect crystals cannot fully meet the requirements of a particular equipment.”

“A good example of this is tungsten carbide and cobalt. The addition of cobalt to tungsten carbide increases the material’s crack resistance, making it extremely valuable in applications. New methods change mechanical properties We can investigate the why and how.’ We reveal the properties of these multiphase systems at the atomic level,” said study leader Alexander Kvashnin, professor at the Energy Transition Center.

For more information:

Faridun N. Jalolov et al., Mechanical properties of single and polycrystalline solids using machine learning, Advanced theory and simulation (2024). DOI: 10.1002/adts.202301171